Abstract

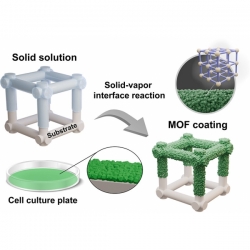

A general fabrication method for metal–organic framework (MOF) coatings through a vapor sublimation and deposition process is reported. The vapor-phase fabrication mechanism relies on the interplay between thermodynamic properties and the solid–vapor interface reaction. The processing parameters of ion concentration, vapor pressure, and system temperature enable control of the sublimation rate, and ion–linker nucleation and coordination reactions occur at the dynamic solid–vapor interface to form the proposed MOF coatings. The reaction rate is controllable and is proportional to the sublimation rate during the fabrication process. On the basis of the proposed fabrication mechanism, experiments are facilitated to obtain combinations of multiple metal cores and a variety of functionalized linkers for vapor deposition from solid solution sublimation. The fabrication process involves pore size control, crystalline orientation customization, and encapsulation of cargo to form composite coatings, and these processes are implemented during the same one coating fabrication process. The initiation and manipulation of the nucleation radius and thus the nucleation rate are easy to control and are related to the fabricated MOF coatings with tunable crystalline morphologies. Moreover, the MOF coating thickness is a time-dependent process that is proportional to the sublimation rate and deposition time. In the present study, the surface area of the fabricated MOF coatings was 1250 m2/g, the Young’s modulus was 2.8 GPa, the surface roughness was 238.7 ± 17.3 nm, and thicknesses ranging from 200 nm to 5 μm were prepared. Maximized compatibility is also discussed through the exploitation of solid solutions that are free of organic solvents and a purely dry process, and the final MOF coatings are conformal with high fidelity regardless of the substrate material type and the complexity of the geometries in both 2D and 3D. The stability of the MOF coating is inspected by an adhesion test that reveals the highest adhesion standard in the ASTM D3359 classification. The cell culture on this coating verified high cell viability with promoted cell attachment, proliferation, and increased osteointegration activities.

KEYWORDS: metal−organic framework, coating, vapor sublimation,multifunctionality, chemical vapor deposition.png)